We provide comprehensive services – from design, through the creation of foundry tooling and casting production, machining, and painting, to assembly and shipping.

We have several thousand types of ready products in the offer for various industry branches.

What do you gain with comprehensive service?

significantly reduced production time for castings

only 3 to 5 weeks from the completion of technical documentation to the delivery of finished castings!

optimised production costs

the entire process is completed in one place.

product ready for implementation

no need for additional machining, cleaning, or painting.

highest quality guaranteed

achieved through the use of cutting-edge technologies and quality control at every stage of the process.

Our team consists of experienced engineers and technologists with high qualifications in mould technology, moulding and core sands, metallurgy, as well as design engineers who create and prepare foundry tooling documentation.

We prepare documentation based on drawings of parts or ready castings provided by the client. We offer consulting and seek optimal solutions.

Based on developed construction documentation, we produce new complete foundry tooling – moulding patterns, mould bases, and core boxes.

This work is performed using modern CNC machine tools. We can also adapt existing patterns to moulding to the technical requirements of our foundry.

The team of engineers in the technological and design department uses MAGMASOFT for casting process simulations and the SOLID EDGE software in their daily work. The team also has access to a 3D scanner.

We prepare modelling of:

• Cast iron, steel of a lifespan up to 100,000 moulds

• Aluminium of a lifespan up to 40,000 moulds

• LAB material of a lifespan up to 100,000 moulds

At our foundry, we produce items from grey and ductile iron. The melting process is carried out in three OTTO Junker induction furnaces, each with a 6-tonne capacity, allowing us to achieve molten metal with any desired chemical composition. For ductile iron production, we use the flexible core wire method (PE).

Quality control in the melting stage includes analysing the chemical composition of both the input materials and the molten metal in the induction and pouring furnaces. The chemical composition is tested in our central laboratory, equipped with a SPECTROMAXx emission spectrometer.

Moulds are created with the use of bentonite sand technology. Moulding is performed on automatic moulding machines:

The high efficiency of the DISAMATIC moulding line allows us to fulfil orders quickly and on time. DISAMATIC technology ensures high quality and consistency in the castings produced.

Core production technologies:

Mould pouring is carried out using pouring furnaces (pourers) by ABB for horizontally parted moulds and OTTO Junker for the vertically parted DISAMATIC moulds. All pourers are equipped with inductors that provide continuous monitoring of the molten metal temperature, and the pouring process is conducted using optical pyrometers to control the temperature of the molten metal stream. Additionally, in the production of ductile iron castings, a nitrogen protective atmosphere is created in dedicated pourers.

We clean the castings using drum and hanger shot-blasting machines, which ensure excellent surface quality for raw castings.

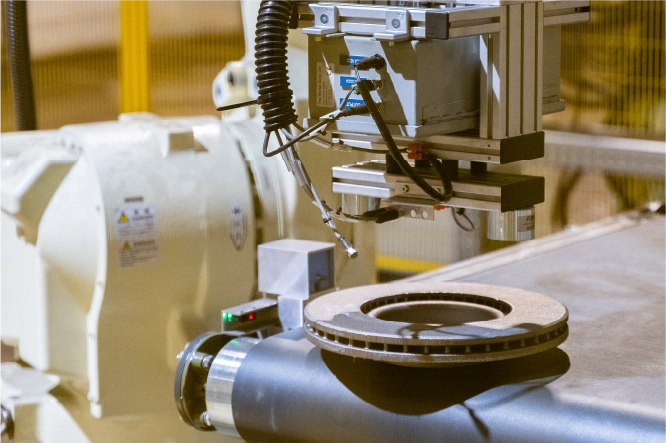

In our CNC department, equipped with machining centres, we perform mechanical machining of castings and foundry tooling based on technical documentation provided by the client or developed by our engineers.

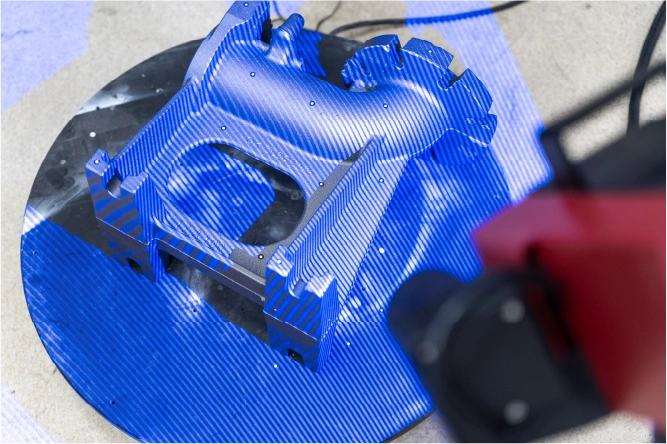

Castings are painted using an immersion method with water-based or solvent-based paints tailored to customer requirements.

Throughout the production process, we employ various quality control methods to ensure high quality and consistency of final product parameters.

After cleaning, each component undergoes detailed visual inspection. Our in-house laboratory conducts the following tests:

We offer the following packaging options for finished products: