We provide full support throughout the production process, from the preparation of design and technological documentation, through the creation of foundry tooling, casting production, machining, painting, to assembly and final delivery.

We hold a licence from the Ministry of Interior and Administration for manufacturing and special trade, as well as the WSK certification.

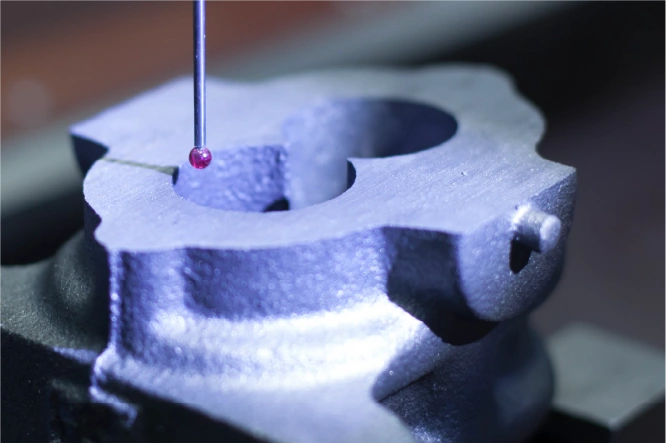

We guarantee a swift product implementation time and consistently high quality for both raw and machined castings. We systematically invest in innovative technologies which allow us to expand our production offer and better align with customer needs.

We ensure our growth is environmentally friendly by implementing energy-efficient technical solutions that reduce the negative impact of production on the environment. More than half of the electricity consumed by the foundry is sourced from renewable energy. We operate under an Environmental Management System and Quality Management System in accordance with ISO 9001:2015 and ISO 14001:2015 standards, certified by QS Zurich.

Years

of experience

Export

countries

Parts

always in stock

employees

Our mission is to produce high-quality castings that meet our clients’ expectations, delivered on time with a commitment to caring for our employees. We prioritise adherence to the highest process and quality standards, continuous improvement, and concern for the natural environment.

The construction of Zakłady Metalurgiczne Maszyn Rolniczych (the Metallurgical Plant for Agricultural Machinery) in Sklęczki near Kutno began, along with the initiation of collaboration with the Japanese foreign trade corporation NICHIMEN. The acquisition of a Japanese patent for the production of ductile iron.

Commissioning of the foundry for operation. Implementation of a Quality Management System according to ISO 9002 standards.

Start of ductile iron production, with manufacturing for the agriculture and railway sectors.

Implementation of Polish Patent No. 130489 titled “Method for Producing High-Quality Machine Cast Iron Using SIC.”

The foundry becomes part of HW Pietrzak Holding sp. z o.o., based in Boryszew Nowy.

The foundry is acquired by Mr. Witold Mikoda.

The foundry becomes part of SHP Centrozap Katowice Sp. z o.o., undergoes privatisation, and is renamed Odlewnia Żeliwa S.A. in Kutno. The ISO 9001 Quality Assurance System is implemented.

The ISO 14001 certification.

Odlewnia Kutno becomes a Member of the Foundry Chamber of Commerce.

Obtaining a license for the trade of explosives, weapons, ammunition, as well as products and technology intended for military or police use.

Licence from the Ministry of the Interior and Administration (MSWiA) for manufacturing and special trade

Key directions of our quality actions:

The management team at Odlewnia Kutno consists of experienced experts who combine extensive technical knowledge with many years of industry experience. Thanks to their dedication and vision, the company is growing dynamically, with a strong focus on innovation and modern technologies.

The managers at Odlewnia Kutno prioritise continuous staff development by investing in training and advanced production solutions, enabling the company to maintain high-quality standards and market competitiveness.

Anna Jurosz-Rys – Member of the Management Board